Free Safety Stock Calculator - Optimize Inventory Management

Our comprehensive safety stock calculator is an essential tool for businesses and supply chain managers who need to optimize their inventory levels and prevent stockouts. This calculator helps you determine the optimal amount of safety stock to maintain, balancing inventory carrying costs against the risk of running out of products during demand fluctuations or supply delays.

The safety stock calculator uses proven inventory management formulas that account for variability in both demand patterns and supplier lead times. By inputting your maximum and average daily usage rates along with lead time variations, you can calculate the precise safety stock levels needed to maintain service levels while minimizing excess inventory costs.

Use this free safety stock calculator for retail inventory management, manufacturing planning, warehouse optimization, and supply chain analysis. Perfect for inventory managers, procurement professionals, and business owners who want to improve their inventory turnover while avoiding costly stockouts and lost sales.

Safety Stock Calculator

Calculate optimal safety stock levels for inventory management

Daily Usage Patterns

Lead Time Variability

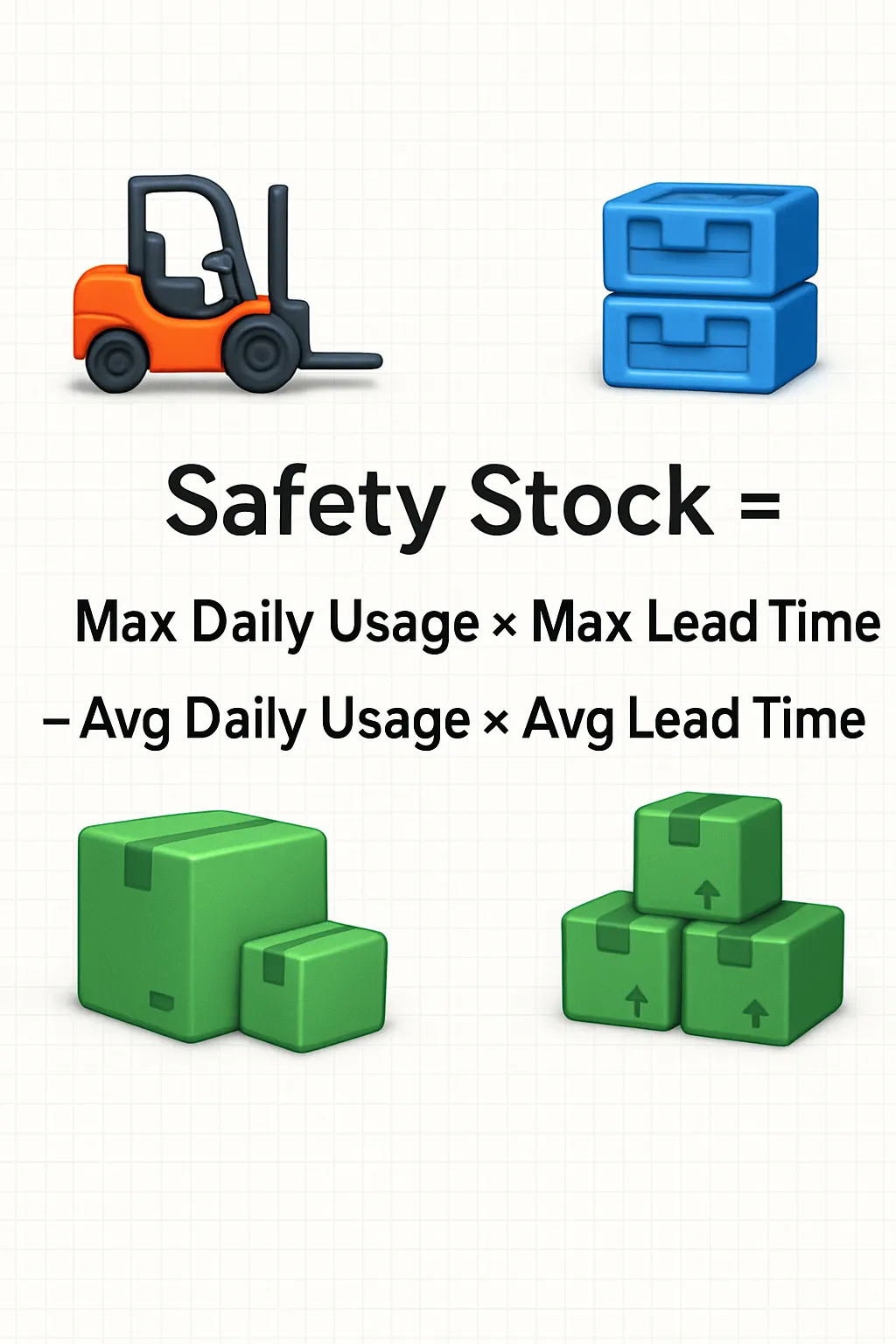

📦 How Safety Stock Calculation Works

Visual guide to understanding safety stock calculations and inventory management

Frequently Asked Questions

Safety stock calculation is the process of determining the extra quantity of an item held in inventory to reduce the risk that the item will be out of stock. It acts as a buffer against fluctuations in demand and lead time.

Safety stock is important because it helps prevent disruptions in manufacturing or customer deliveries due to stockouts, ensuring smooth operations and customer satisfaction.